Categories: all aviation Building a Biplane bicycle gadgets misc motorcycle theater

Mon, 06 Apr 2009

My exultation at the clutch being fixed on the CL175 were, let us say, premature. Possibly foolish. Turns out that when you run a wet clutch without oil, its grip increases. Who woulda guessed?

Indeed, when I checked the oil after that oh-so-successful run, it was off the end of the dipstick. This is disturbing, as I'd checked it before, and it was in the middle of the range. Hopefully that was just me misreading the stick, and not something more ominous.

When I topped up the oil again, the ol' slip-n-slide clutch was back. *sigh*

So, I spent most of today (having taken the day off after a very theater-intensive weekend) in the garage, playing with the clutch.

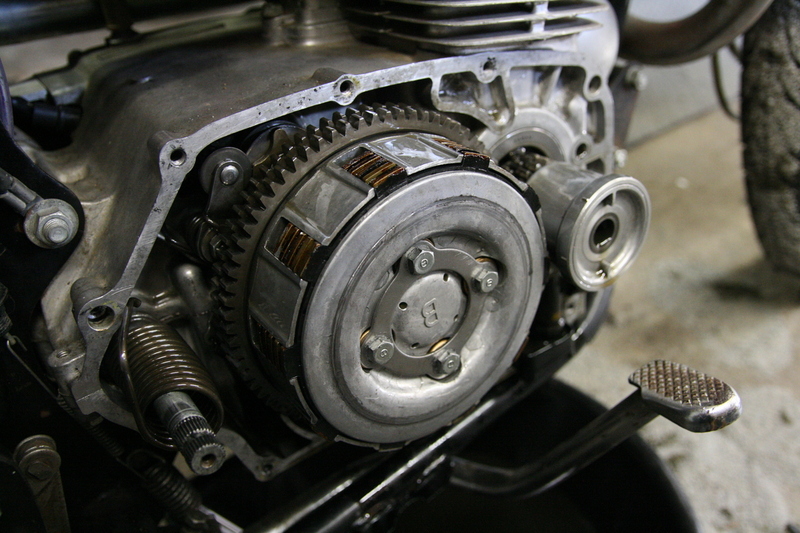

First thing, lemme give you some vocab, so I don't have to clutter up the rest of this little story. The circular thing in the center of that picture above is the clutch.

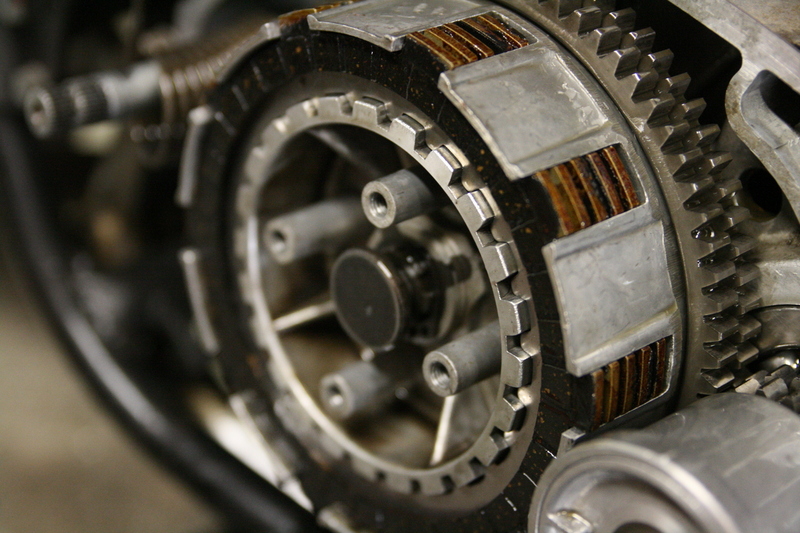

Friction plate: One of 5 discs in the clutch which is covered in a friction material, something like cork. Also called a friction. Visible as the brown-edged fingers in the picture above.

Steel [plate]: One of 5 bare, flat steel discs in the clutch, interleaved between friction plates. Not visible in the picture above, but they're spacing the friction plates apart.

Dished steel: The last steel plate on the engine side. It's just like a normal steel, except that it has a slightly concave shape. This allows it to either push the stack out (like in the picture above, note the gap between the last brown friction plate and the back of the clutch basket), or allow it to go closer to the engine.

Pressure plate: The outer-most plate of the clutch, it's the big silver plate you can see with the upside-down B marked on it.

Ok, so the previous owner did a bunch of stuff with the clutch, he said. He claimed that he installed new friction plates, and new springs. In the condition I got it, none of that was obvious, and today I finally figured out why.

It turns out that the friction plates he got are 3.5mm thick. They're supposed to be 3.0mm thick. He must have installed them all, seen them nearly falling out of the clutch (once you take off the pressure plate, the plates are free to fall out), and decided something was wrong (which it was). Only, he must have figured that he installed that dished steel backwards.

In its stock configuration, the CL175 clutch has the dished steel installed like in the picture: pushing the stack of plates further out. With the correct thickness friction plates, this results in a stack that's the right height when you have 5 frictions, 4 flat steels, and the one dished steel.

Well, he must have figured, that doesn't look right, so the dished steel must go the other way. So he installed the dished steel the other way round, which ends up looking like this:

If you look toward the outer end (this is the view of the clutch without the pressure plate installed), you can see that there's a bit of a gap between the end of the sliver clutch basket (the thing the friction plate fingers slot into). This stack is too short, and this is the state I found it in.

When the stack is too short, the pressure plate doesn't exert enough pressure. It doesn't compress the springs enough. Well, with these extra-thick friction plates, when the dished steel goes the other way, the stack is too tall. This means that, although the pressure plate is now exerting about the right amount of pressure (a bit more than is ideal, but that's better than the other way), it's also so tall that when you pull the clutch lever, the pressure plate hits the cover that normally keeps all this stuff inside the engine. See the first picture, and note the recently-added scuff marks about halfway between the bolts and the outer edge of the plate.

Pulling the clutch lever causes that circle in the center of the last picture to push out. This pushes the pressure plate out. This allows a bit of a gap between all the plates, and the clutch is no longer engaged. It only moves a couple of millimeters, but with this too-tall stack, that's enough to scrape metal against metal in a most ungood way.

Anyway! The practical upshot of all this is that this bike is grounded until I can get the right friction plates. A racing friend says he's got a stack of stock parts he'll send me, so hopefully I'll see that in the mail in the next few days. Then I can put it all back together and it should just work. Finally. I hope.

Posted at 19:28 permanent link category: /motorcycle

Categories: all aviation Building a Biplane bicycle gadgets misc motorcycle theater